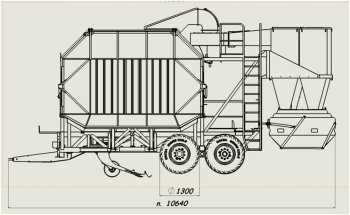

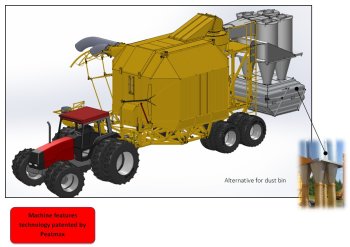

Pneumatic Milled Peat Harvester JIK-40

Efficient, dust-free pneumatic harvester for high-quality peat production

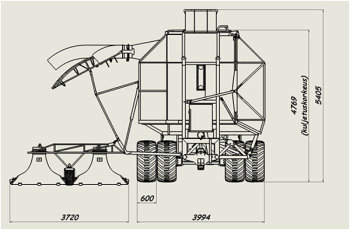

Due to its side-tilting bottom structure, the harvester is particularly well suited for environmental peat production sites. It also fits well for production areas where the push-stacking method is used. The harvester can be equipped with a friction roller or hub motor type auxiliary drive, which makes the compacting of the stockpile easy. Dust separation that is carried out with the secondary cyclones is extremely efficient, without reducing the vacuum power. Dust can be collected into the container located below the cyclones, where from it can be emptied at the foot of the stockpile. Furthermore, the container can be replaced by a dust discharge unit, which deposits the separated dust on the surface of the field. To reduce the weight, the cyclones and the dust container are made of aluminium.

The nozzles follow the surface contour of the field perfectly, even on a rough terrain. They feature many adjustment options, i.a. they can be lifted high into the transport position.

Specifications

| Capacity |

60-90 m3/h |

| Operating speed | 4-10 km/h |

| Load space volyme |

ca. 40 m3 |

| Tyres (8 pcs radial tyres) |

600 x 26.5 |

| Weight |

8100-8800kg |

| PTO |

1000 rpm |

| Engine power requirement |

120-150 kW |

| Nozzle width |

ca. 3,7 metriä |

| Power for the fan |

65 kW (max.) |

| Fan air capacity |

ca. 9 m3 /sek |

| Required hydraulics (non-driven version) | 2 pcs 2-action valves |

| Driven versions | 1 pcs 1-action valve 1 pcs 2-action valve free return |